Longevity

With countless technological achievements designed to promote even wear, Yokohama tires deliver impressive longevity—which means lower operating costs.

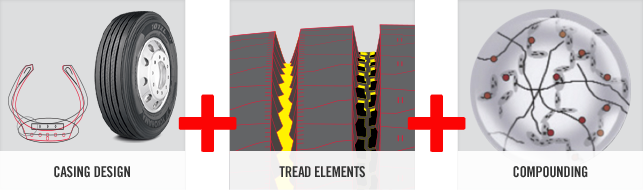

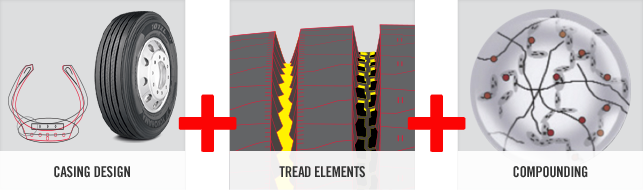

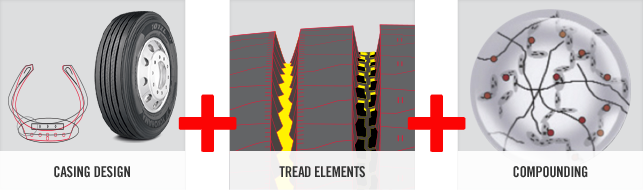

Ingenuity - a tech story

Every facet of our design, development and manufacturing processes demonstrate why Yokohama leads the industry in long-lasting original treadlife.

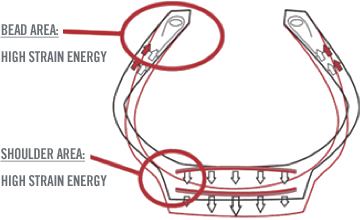

Casing design

Fighting fatigue and stress

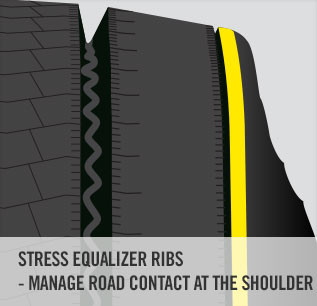

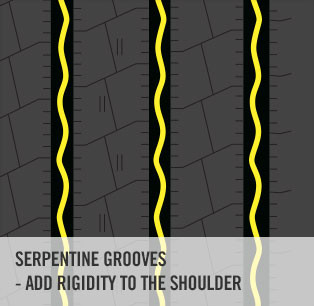

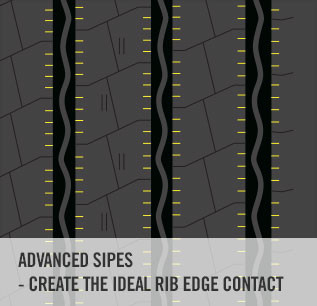

As a tire rotates, the casing flexes as it comes in contact with the road—loading and unloading more than 150 million times over its average lifespan. The constant flexing impacts the two most vulnerable areas of the casing, the bead area and the belt edge. This is why Yokohama has developed technologies to significantly mitigate fatigue, and manage the strains that occur during normal operation.

As a tire rotates, it is subjected to directional strain energies from loading and unloading.

Creating a long-lasting tread

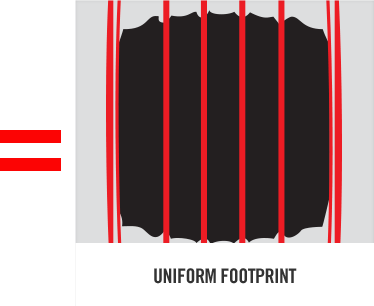

Manufacturing's contribution to regular wear

Conventional tread stock is extruded as a thick, flat piece of rubber and then is forced into a mold which creates the tread pattern. This introduces a lot of stress to the tread stock as it is erratically displaced when it makes contact with the mold. Yokohama has the technology to extrude the tread stock in a pre-formed profile giving the green tire more of a finished product profile before entering the mold. This greatly enhances the rubber distribution of the tread area in the mold. The result is a very consistent and uniform tread which produces a more consistent footprint, which ultimately equates to a longer wearing tire.

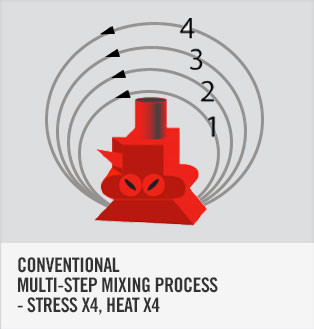

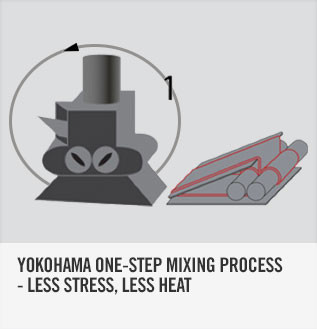

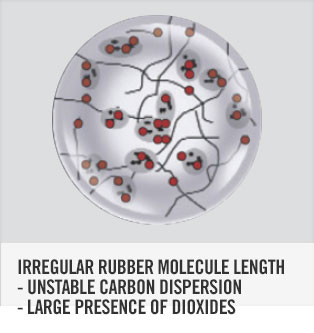

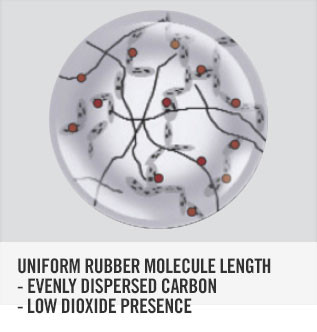

Creating a world-class compound

Our advanced rubber compound is created through a very efficient, environmentally friendly, single-stage mixing process that yields a molecular structure with better carbon distribution with lower dioxide occurrence. The end result is reduced heat build-up in the tread area and significantly lower rolling resistance which allows for deeper tread depths for increased mileage and maximum performance.

Automotive

Automotive  Commercial

Commercial  OTR

OTR